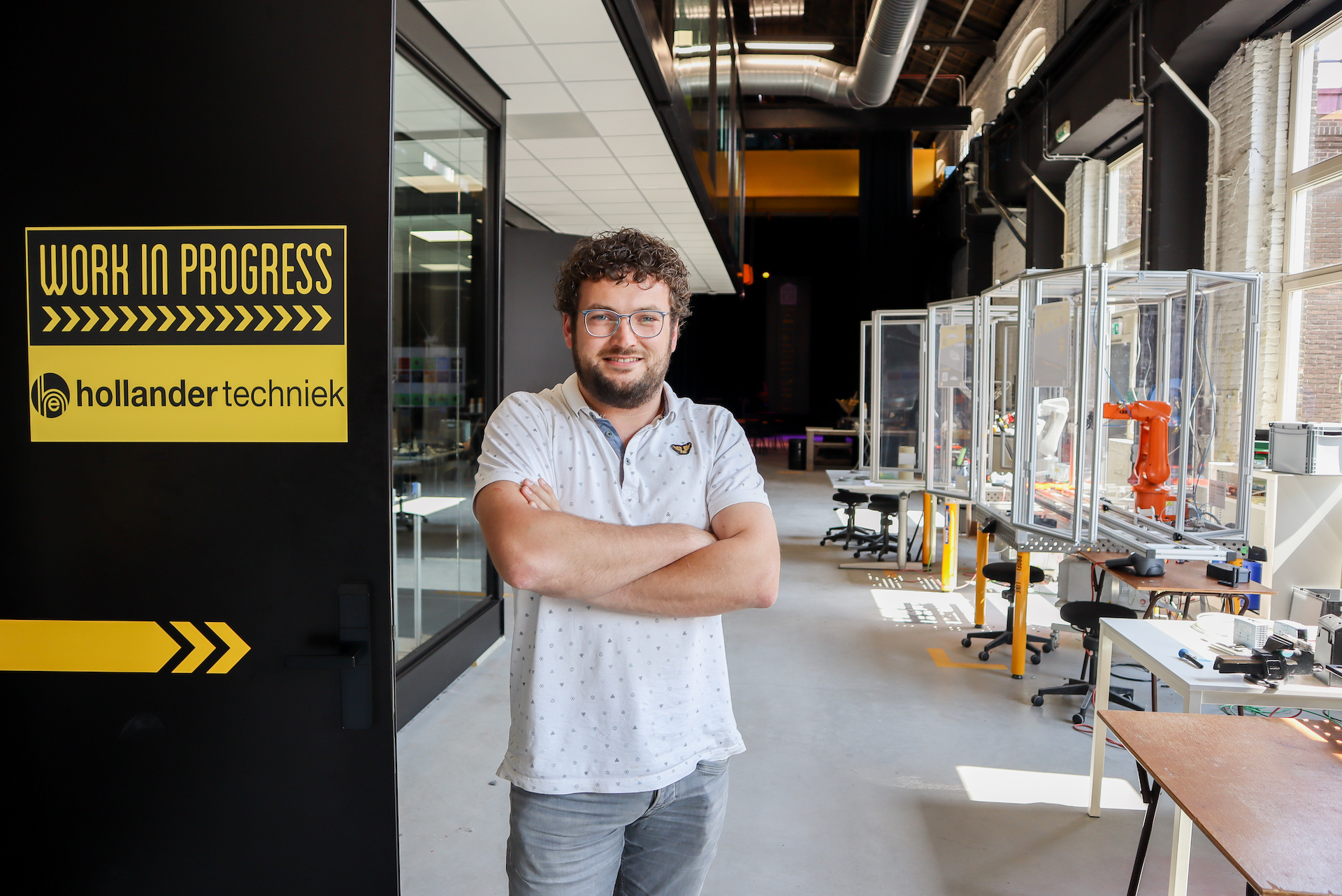

It has been almost ten years since Brent Dekker first stepped in the office of Hollander Techniek. He never left: he now works as a concept engineer. In his role, he is close to the customer and his problem. “I have to immerse myself in what the customer does and know what techniques are available. Together with my colleagues, we then develop a solution,” Brent says. The variety of projects is what keeps him sharp and enthusiastic.

Not the only one

Brent is not the only one who stayed with Hollander Techniek after his graduation. He says: “This applies to approximately two-thirds of the people in my team. An internship is a great way to find out what you like and get a taste of the company. If you like it and you can stay, that’s great! During his graduation, he supervised two other students who were carrying out a sub-study. When he joined the company, he continued to do so. “I really enjoy supervising students”.

Engineer or entrepreneur?

Three years ago Brent started his own company that makes control technology for small companies. “I do that with a lot of pleasure. I make PLC and HMI systems for customised heating installations. The combination of working with my hands in my company and my work as an engineer at Hollander Techniek is great”, Brent says.

At Hollander Techniek, he works with many different techniques, together with his team. He explains what is so great about that: “I have to know a lot about technology. Sometimes that makes me a generalist. On the other hand, I dive so deeply into the customer’s problem to find a solution that I can and may develop as a specialist in some areas.”

Integration of technologies

Brent’s technology portfolio is broad. From programming (Delta) robots to implementing Vision Technology and 3D simulation. “At Hollander Techniek we do not build our own machines, but we integrate technologies for solutions at our customers. Specifically for a customer demand we research a technology, a market development or application in machine. What we learn and develop, we can then apply to other customers as well.” Brent says. According to him, the most important challenge makes it exciting: putting everything together into a working whole.

A good example is the use of 3D simulation. Brent: “In the current market, it is sometimes very difficult to get components. 3D simulation offers a solution. We can test the technology before the actual components are available. The cool thing is that with 3D visualisation you can also walk around in your design with VR glasses.”

Technical playground for adults

Brent can be found at Perron038 more and more often. Not only for supervising students, but also for the rollout of the shared facility that will start later this year. “With an enthusiastic group of people, we determine which machines and facilities we would like to have at Perron038. To make joint use of. The common thread is becoming clearer and clearer, so that soon we will have a real Factory of the Future that will benefit all partners”. Brent tells.

He sees Perron038 as a technical playground: ‘the toys get bigger’. “The open character of Perron038 is very strong. Partners do not compete with each other for customer projects. But we do exchange ideas about technical matters. When you are here, you can just walk up to a system and talk to each other about it. That often takes you just that bit further.”

Point on the horizon

When asked whether Brent gets any energy from the role he fulfils, he gives a resounding yes. “I find it very interesting to keep up to date and to see where we are going in the industry. That’s what we need to keep focusing on: continuously learning about new technology and making it applicable to our field. In my role, I can make a very concrete contribution to this. Together, we strive for solutions that are as smart, efficient and future-proof as possible. Every day again.”

Curious about the internship, graduation and job opportunities at Hollander Techniek? Check their vacancies here »